Consumer

Consumers are usually attached to the long-distance heating net with a quantity regulation. The size of the mass flow depends on the amount of heat needed by the consumer as well as on the entry temperature with which the installation is reached. There is therefore – as long as the difference of pressure at the consumer between flow and return is sufficiently big – no actual direct dependence of the consumer mass flow on the difference of pressure. Flow and return are hydraulically decoupled at the consuming devices.

With the modelling of the heat extraction of consuming devices, their mass flows take and the return temperatures, the different consumer types must be considered.

Consumers differ according to their kind of heat requirement (room heating, hot water preparation, air conditioning or special industrial heat requirement) and their individual temporal consumption behavior (e.g. private households, authorities, industrial plants, schools). A further distinguishing characteristic is often additionally the year of construction of the heating system, since the design output for the same room size has continuously decreased over the course of time. Thus a heat consumer, whose installation dates from the year 1980, surely achieves a smaller maximum extent of utilization relative to the nominal output than consuming devices built in 2000.

These characteristics which vary strongly due to plant construction and individual behavior, lead to the development of consumer models which can be calculated with knowledge of the consumer heat requirement (this can also be divided into room heat and hot water requirement) and the physical sizes relevant for a network calculation such as mass flows and return temperature.

Due to the high number of consumers, for network calculations (this is valid also for electricity, water and gas network calculations), it has proved satisfactory not to record a network branch in the model for each consumer but to concentrate on the consumer loads at the nearest network node points.

In the course of the development of the simulation for long-distance heating systems developed by Icking extensive investigations and model calculations for the description of the consumer behavior were carried out by Loewen ; for the simulation of whole long-distance heating nets, the detailed and often also complex modelling of the individual consumers did not turn out to be practicable. So it has little sense to illustrate the technical part of consuming devices with high accuracy if a by far larger model uncertainty is caused by the individual behavior of the consumer.

Therefore a simple simulation model was selected, in order to illustrate the consumer behavior from view of network simulation sufficiently exactly and at justifiable expenditure. This model should be adaptable to usual characteristics of the consuming devices:

- In the case of increased temperature drop and constant entry temperature a increased return temperature results,

- With constant heat extraction the return feed temperature only changes slightly when the inlet temperature changes.

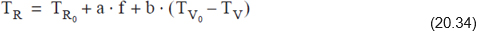

On the assumption that these two effects can be described by a linear approximation, it leads this to the following conditional equation for the return feed temperature TR of the consumer:

In Gl. 20.34, f defines the load factor, defined as quotient from actual, temporal temperature drop Q and the nominal connected load Q0 :

The values for the design return temperature TR0 , the design entry temperature

TV0 , the nominal connected load Q0 as well as for the two adjustment coefficients a and b are therefore configuration parameters for the modelling of the consuming devices.

Since the load factor cannot be determined for each consumer, it is possible to define different consumer groups whose different configuration parameters TV0 , TR0 , a and b can be assigned. Also the allocation of a special load prognosis to individual consumer groups is possible.

After calculation of the consumer return temperature TR with Gl. 20.34 the determination of the mass flow then takes place m· as follows:

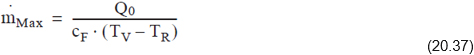

The decrease mass flow of a consumer leaves can therefore also be described as a product of the momentarily maximum decrease mass flow m· max and current load f where the maximum decrease mass flow is calculated as follows:

Modelling of the under supply of a consumer

Since the decrease mass flow of a customer is generally limited by a mass flow delimitation, the mass flow calculated from Gl. 20.34 should potentially be limited to the maximum mass flow calculated according to Gl. 20.37, especially for the calculation of low load cases. A smaller actually removed performance may result. The corresponding consumer is marked with the error code under supply and a warning is given.

For the supply of an customer installation a minimum pressure differential or a minimum pressure at entrance is usually guaranteed. Under supply can also result for consumer behavior when these guaranteed conditions are broken. At present the pressure/ pressure differential restrictions of the consumers are only checked and a warning issued when they are broken.